The company’s new State-of the-Art plant (also knows as Unit 2) in Kakkanad Cochin (Kerala) is the pride of S.T.Reddiar & Sons (EKM), it stands as a symbol for our vision of customer satisfaction and one stop print shop.

Unit 2 is situated in a 2 hectare land with ample space and facilities for truck movement and loading, the facility also has specialized equipments to handle very large and heavy cargo. There is a very large area for storage of Materials, which is completely fire, static and lightning safe.

It is conveniently located in the outskirts of the city with full access to the Railways, Airport, Seaport and the National Highways(Roadways) in very close proximity. This plant also has a 24 hours Power (Back up).The Unit is currently serving as our main Sheet Fed and commercial Heat Set Web division.

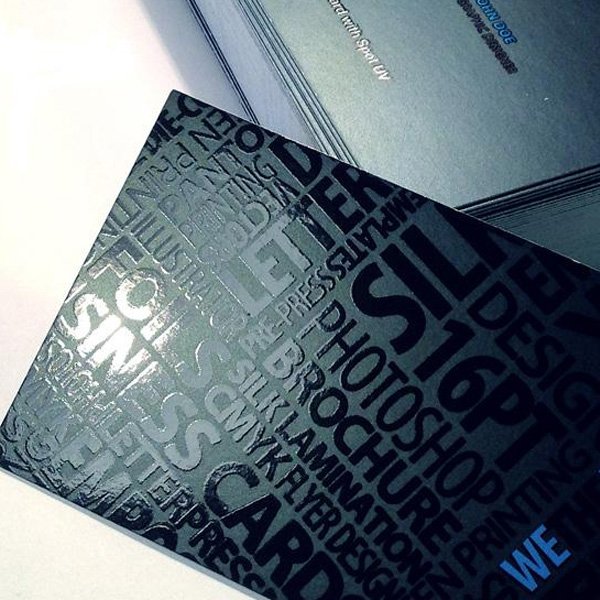

It Houses a Full Range of Pre Press, Press and Post PressEquipments which have been procured form some of the industry leaders in Print Equipment Manufacturers.

Unit 2 houses a brand new Komori LS29 6 Color + Coater, UV, H-UV Sheet Fed Press Which is the first of its kind in India.

Introducing UV and Fully Automated 'AI' sheetfed concept and also S.T.Reddiar & Sons (EKM) is proud to introduce for the first time in Kerala 'On-Demand Offset' print solution.

This machine is flexible enough to print thin stock to very thick boards,and with UV it can also print on all type of plastics, pets and films, from thin transparency sheets to Credit Cards.

It also is capable of handling ULTRA SHORT RUN with Zero Turn Around and drying time,(On Demand Offset)efficiently and in a cost effective manner, via H-UV printing. It can produce 500 sheets front and back in record time of 12 minutes.

Technology used in it allows to switch over to UV with just a click of a button it can handle medium and long run jobs and Packaging Jobs like a sheetfed machine also very efficiently and in a cost effective manner.

It also showcases the first Komori System 35 SII, Commercial Heat Set Web Offset Press in Kerala designed specifically formagazine and Publication Printing works.

It is designed to handle LWC (light weight coated paper) very efficiently which has become very popular among publishers in Kerala from the time it was introduced by us in 2007.

Additionally it also houses a range of Cold Set Web Offset Presses and Sheetfed offset presses designed for Publication,Commercial and Packaging print requirements.

Unit 2 also has a Miller TP 38 (German Made) 2+2 Perfecting Press which can be used as a straight 4 colour machine or 2 or 1 colour perfecting press (Simultaneous front & back printing).

A web press 2 colour which can print publication jobs 16 page 2 colour or 32 page single colour (A4).

Unit 2 houses a complete PRE PRESS solution with the Computer to Plate Equipment fro Dainippon Screen Japan, this is backed by a powerful workflow from Fujifilm.

The workflow has complete end to end solution from basic imposition to color management and proofing which also includes an exclusive online 3D proofing, where customers can see their job as it would be after printing and finishing, from their own computer screens in 3D.

Since the same workflow is integrated to our Head Office, our customers can submit their job in any of our units and would be able to see their proofs and approve.

Our pre-press is also connected to all our printing machines with CiP connectivity, for super accurate color control.

Unit 2 is perhaps one of the largest or if not 'The' largest Post Press in Kerala.

It comes with a complete Book Binding Solution that includes a fully Automated Muller Martini Six Station Saddle Stitcher with an online 3Way trimmer, this machine is capable of going up to speeds of 8000 books per hour.

A newly accrued 27 clamp Golbus high speed Perfect Binder with gatherer and 3 way trimmer, can do upto 5000 perfect bound books in an hour.

Section Sewing Machines and 2Heidelberg Stalh High Speed Paper Folding Machine.

Introducing. Dry-Lamination

Another 'first in Kerala' from us is the new Dry-Lamination machine from Yii Leean industry leader in dry-lamination technology. Dry-Lamination allows super fast turnover of lamination jobs for our customers, with speeds of upto 10000 sheets per hour. It also has a powder removing unit which will automatically remove the Anti-Set off powder uses in all offset presses.

It is cost effective via media which enable the customers to enjoy the quality of Thermal Lamination technology at very low cost which is almost at par with conventional glue lamination, at same time faster and way better quality of output.

Introducing 'On Demand Die Cut' Solution.

The Concept enables our customers to do ultra short run, short run or medium run die cut in much more cost effective way in just the time needed make a 'die' for conventional die cutting. For More info on this please Contact our Customer Service Executives

The Kakkanad unit is situated in a 2 hectare land with ample space and facilities for truck movement and loading, the facility also has specialized equipments to handle very large and heavy cargo.

There is a very large area for storage of Materials, which is completely fire, static and lightning safe.

It is conveniently located in the outskirts of the city with full access to the Railways, Airport, Seaport and the National Highways(Roadways) in very close proximity. This plant also has a 24 hours Power (Back up).